Modern industrial manufacturing innovates via efficiency and accuracy. RM Mold, a sheet metal pressings leader, improves quality, consistency, and performance across sectors. RM Mold manufactures reliable automotive, aerospace, electrical enclosure, and appliance parts. With modern technology and years of manufacturing expertise, RM Mold redefines metal forming quality.

Sheet Metal Pressing Innovation and Precision

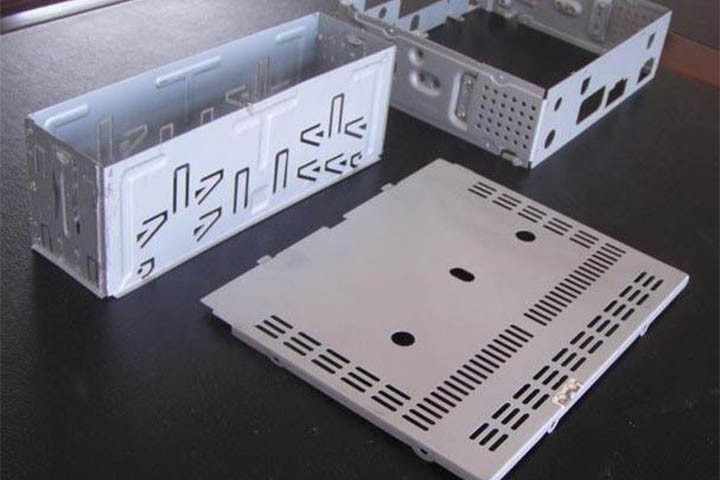

Sheet metal presses manufacture robust, accurate pieces. RM Mold designs each pressing process exactly using cutting-edge technology and research. Controlled press operations turn flat sheets into intricate pieces.

Modern RM Mold manufacturers create components with precise tolerances and design requirements. We save waste and boost efficiency on every project. From microscopic electronic bits to large structural components, RM Mold's production standards assure quality and reproducibility.

Technology for Metal Sheet Pressing

Every excellent metal product utilizes a strong metal sheet pressing machine. RM Mold uses precise presses for steel, aluminum, and copper. Sheet metal is accurately shaped without damage with these tools.

RM Mold updates its manufacturing line automation and digital control. This unique method boosts efficiency, decreases human error, and assures product correctness. Intelligent monitoring systems optimize production and turnover.

Why RM Mold Leads Sheet Metal Pressings

RM Mold is creative, experienced, and trustworthy in sheet metal pressings. The company's expert engineers ensure technical and functional compliance with clients from idea to completion. The firm handles difficult designs using its material behavior and mechanical processes knowledge. With RM Mold, companies can produce huge volumes at low cost without losing quality.

Advanced CAD/CAM design tools let RM Mold achieve blueprint-to-pressed product perfection. Custom tooling and die-making provide project management flexibility.

Outstanding Equipment: The Backbone of Metal Sheet Pressing Machine Efficiency

Every RM Mold metal sheet pressing machine is dependable and effective. These machines are speedier and more precise with servo-driven controls, automated feeding, and quick-die changing.

RM Mold's low- and high-volume production facilities ensure flexibility. The devices can handle different sheet thicknesses and metal grades, giving clients full flexibility. Precision-engineered dies and molds ensure brand geometry and surface finishes throughout production batches.

Preventive maintenance helps RM Mold decrease downtime and maintain output quality. New technologies and technical skills provide a precise, efficient, and reliable manufacturing ecology.

Sheet metal press uses across the industry.

Due to their versatility, sheet metal pressings are vital in many industries. RM Mold has automotive, electronics, energy, and home appliance customers. Automobile engine brackets, body panels, and chassis systems require pressing. They support electronics and housings. RM Mold meets worldwide quality requirements for each sector with our production expertise. Design-specific pressings increase fit, strength, and performance. Companies seeking precision-engineered metal components worldwide choose RM Mold because of its versatility.

Precision Metal Engineering using RM Mold

RM Mold hires talented, innovative, and quality-focused professionals. The organization efficiently completes projects from concept to mass manufacturing. The experience in sheet metal pressings and metal sheet pressing machine operations makes it trusted by accuracy and durability-focused businesses. Modern technologies and customer service help RM Mold revolutionize precise engineering and metal manufacturing.

Write a comment ...