One of the components of modern manufacturing is metal press stamping, which is particularly important in the business, where the output has to be precise, effective, and consistent. This process is applied with a press machine and is used to shape or cut pieces of metal into specific shapes, ensuring that, nevertheless, each part is identical. who want to improve their sheet metal manufacturing operations need to know the basics of metal press stamping.

Understanding the Process of Metal Press Stamping

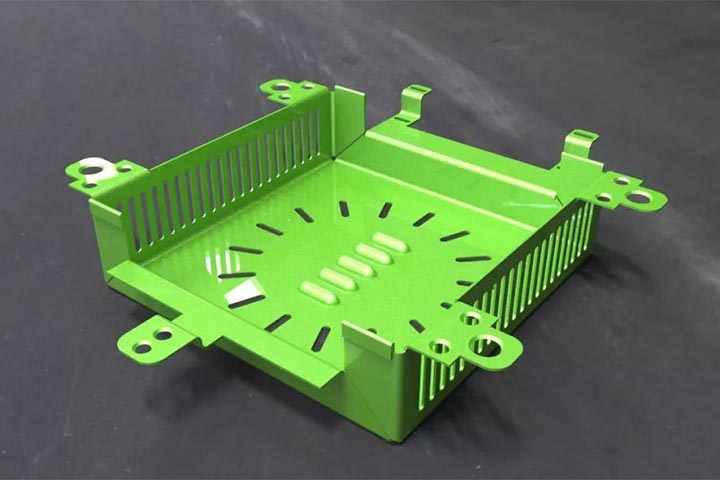

Putting a metal sheet between a die and a punch is the most basic part of metal press stamping. The press uses a controlled force to cut, bend, or shape the metal into the shape you want. With this method, you may make many products while keeping the quality the same. Press stamping is more accurate than other metal forming methods, which cuts down on waste and makes better use of materials.

Sheet Metal Stamping Techniques for Industrial Applications

There are many ways to do sheet metal stamping and each one is best for a certain job. Blanking cuts a flat portion out of a metal sheet, while punching makes holes or specialized cutouts. You can make complicated angles and forms by bending and shaping things. Deep drawing turns metal sheets into complex 3D shapes that are often utilized to make cars and appliances. Picking the proper method makes sure that the work is done quickly and cuts down on the need for more processing.

Benefits of Metal Press Stamping in Mass Production

One of the best things about metal press stamping is that it can be used for large production. The technique makes parts that are always excellent quality and come out quickly. It also cuts down on waste, lowers labor expenses, and lets you make shapes that could be hard or impossible to make with other processes. Metal press stamping is very important in fields including automotive, aerospace, electronics, and home appliances because of these benefits.

Common Materials Used in Sheet Metal Stamping Projects

Metal press stamping can be used on a wide variety of metals, such as aluminum, copper, mild steel, and stainless steel. Material to be used will depend on the strength, flexibility and resistance to corrosion of the application. You have to understand how materials behave in order to achieve the desired outcome in stamping work.

Tips for Achieving Precision in Metal Press Stamping

To achieve accurate metal press stamping, you must have good dies and a machine that is correctly calibrated. To minimize errors and ensure that any parts that are stamped are identical, you must perform routine maintenance, ensure that everything is lined up, and properly handle materials.

Innovations in Sheet Metal Stamping Technology

With the implementation of new technologies, such as the use of new stamping machines controlled by CNC and automated systems to manage materials, it has changed the way that sheet metal stamping is done. All these new ideas render things faster, more accurate and dependable, and this allows the manufacturers to satisfy the growing demand without reducing quality.

RM Mold is a trusted partner for organizations that want the best sheet metal stamping and fabrication services. RM Mold makes high-quality parts quickly because they know how to do metal press stamping, CNC machining, and precision manufacturing. Check out their services today and see how they bring efficiency, accuracy, and new ideas to every project.

Write a comment ...