If you look around any modern workshop or manufacturing floor today, chances are you’ll spot a CNC laser machine humming away somewhere in the background. And honestly, it makes perfect sense. When you need metal parts cut cleanly, quickly, and with almost zero fuss, a CNC laser cutting service is usually the first thing people think of.

What makes it different from traditional cutting?

Traditional cutting instruments deteriorate, blades get blunt, and the procedure slows down with time. On the contrary, using lasers means no physical contact, so one could avoid all those problems. Sophisticated forms, sharp angles, and tiny apertures — the laser smoothed them all and silently. In case of intricacies in your design, CNC laser cutting proves to be more efficient than the majority of non-mechanical methods.

Why do companies look for a metal laser cutting service?

When people search for a metal laser cutting service, they’re usually after three things: clean results, fast turnaround, and accuracy. And laser cutting checks all three boxes easily.

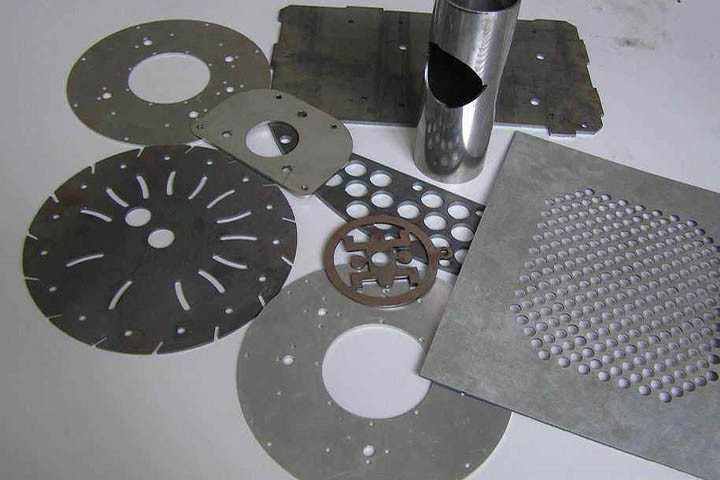

It’s especially helpful for:

Sheet metal fabrication

Custom brackets

Enclosures

Machine parts

Decorative metal panels

In every industry — automotive, electronics, construction, or even art and design — laser cutting proves to be a dependable method to convert a digital design into a physical metal part without postponing the schedule.

Final thought

A CNC laser cutting service is among the safest options if your project requires precision and you do not wish to take a chance with quality. It is fast, exact, and gives off a look that is neat look. Clean and precise parts in manufacturing make the rest of the work smooth as well.

Write a comment ...